NEWS&EVENTS

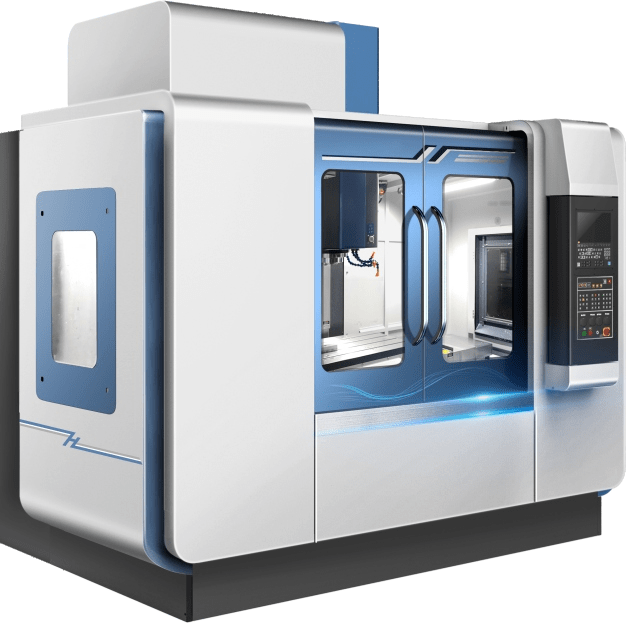

In 2018, a high-end CNC machine tool manufacturing base was established in Ningbo, Zhejiang

The characteristics of a good machine tool

The first is the design of the machine tool, which is the soul of the machine tool. The second is the casting of the machine tool, the casting is the skeleton of a machine tool, is the protection of cutting torque and scattered vibration, and is the basis for stabilizing the reliability of the whole machine. In addition, the processing and assembly process is an important link to effectively ensure the improvement of accuracy and reliability; The system is the key to determine the accuracy and reaction of the machine tool and the running speed. Industrial components such as lead screws, wire rails, bearings and spindles are an important part of ensuring accuracy.

Why our machine tools have been used for many years and still have high accuracy?

First of all, in terms of machine tool design, the design is the soul of the machine tool, followed by the casting, the casting is the bone of the machine tool, is the protection of cutting torque and scattered vibration, and is the basis for stabilizing the reliability of the whole machine.

Secondly, it is the casting of the machine tool, the casting is the skeleton of a machine tool, is the protection of cutting torque and scattered vibration, and is the basis for stabilizing the reliability of the whole machine.

Again, the system is the key to determining the accuracy and reaction of the machine tool and the speed of operation. Our machine tool system adopts a modular structure, which is easy to disassemble and assemble, and the control board is highly integrated, so that the reliability has been greatly improved, while completing the quadratic evolution, improving the functionality and intelligence, ensuring efficient and modular, and more flexible in programming

Finally, industrial components such as lead screws, wire rails, bearings and spindles are an important part of ensuring accuracy. The HALLERBS machine screw is equipped with high precision C1 class with hollow cooling to reduce the variation of cold and heat and ensure long-term accuracy.

Intelligent digital factory model

Based on digital management, applying intelligent logistics and intelligent warehousing to promote the expansion of customer intelligent manufacturing to a deeper and wider range of fields

Strong introduction of high-quality bed in 2024

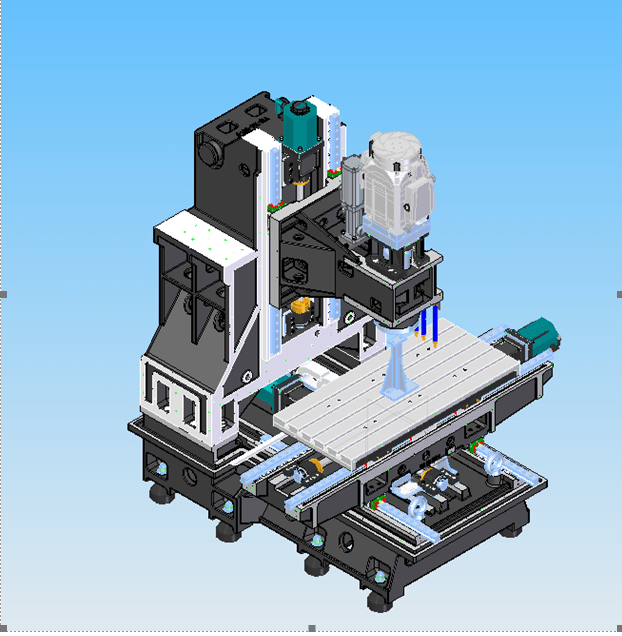

1. Four groups of FAG bearings are adopted

2. High precision headstock

Double cable-stayed seven symmetrical stiffeners

3. Spindle system

The BIG-PLUS spindle system guarantees better rigidity and accuracy of the tool holder at high speeds and in complex cutting conditions, eliminating Z-axis variations.

Main features of screw nut holder

1. Six sliders and integral screw nut holder

Six sets of bearings, double predrawing, double positioning, greatly improve reliability

2. The casting is reheated twice

The casting adopts two reprocessing and artificial aging to restrain the deformation constraint

3. C2 level lead screw

High grade for excellent rigidity, machine accuracy and repeatability

Column characteristics

1. 45mm roller rail

2. Uprights

The column adopts Mizi wind circuit design to ensure rigid seismic absorption and thermal deformation

3. Unique ATC installation structure design

The unique ATC installation structure design, the tool store is installed on the support surface of the column, the weight of the tool store is directly transmitted to the foundation of the machine tool, which can be better supported than the suspended tool store, and can avoid the deformation of the machine tool column

4. Heavy Duty type 6 slider

High rigidity guarantee

5. Symmetrical counterweight structure

6. Wall column

CONTACT US

Please contact us, I will reply to you on time within 6 hours. Thank you very much for your trust!

https://www.google.com/maps/place/%E4%B8%AD%E5%9B%BD%E6%B5%99%E6%B1%9F%E7%9C%81%E5%AE%81%E6%B3%A2%E5%B8%82/@29.8699757,121.407152,11z/data=!3m1!4b1!4m6!3m5!1s0x344d6354630858f7:0x948723f846ccf173!8m2!3d29.868336!4d121.54399!16zL20vMDFsMzNs?hl=zh-CN&entry=ttu+8617706680382

Add: Ningbo City, Zhejiang Province, China

Tel: +8617706680382/+8615314529837

Email: cncmachine.dept1@hoporogroup.com

info@hoporogroup.com