Steady growth, taking pride in customers, integrity and harmony, diligence and pioneering

Steady growth, taking pride in customers, integrity and harmony, diligence and pioneering

We are the manufacturer of tapping machines and also the user of tapping machines!

Ningbo Hoporo Tech Co., Ltd focuses on the research and development of automation equipment. It has successively developed non-standard and special shaped nut tapping equipment such as wheel nuts, blind hole nuts, rivet nuts, sleeve nuts, round nuts, T-nuts, welding nutsand other supporting equipment related to nuts, mainly for high-end product manufacturers with high difficulty, high precision and high requirements such as auto parts, ships, aerospace, etc. The products are sold all over the country and international markets such as Europe, America, Southeast Asia, and the Middle East. With reliable quality and good service, they are deeply trusted and praised by domestic and foreign customers.

And it has a fully automatic nut tapping machine production line for automotive parts. The entire production line has a total of 45 tapping machines. Each tapping machine has automatic loading, automatic unloading, punching, small holes, no material and other alarm functions, and can be remotely assisted (download, change program).

Highlights of Remote Assistance Upgrade, Unlock New Production Experience

Compared with the traditional operation and maintenance mode, our upgraded remote assistance function has achieved three major breakthroughs: "comprehensiveness, high efficiency, and high safety", covering the operation and maintenance needs of the entire production process, and each highlight directly addresses customer pain points:

Highlight 1: Remote Diagnosis, Second-Level Response Without Delay

Highlight 2: Remote Debugging, More Convenient Program Upload and Download

Highlight 3: Remote Guidance, More Worry-Free Precision Operation and Maintenance

Highlight 4: Industrial-Grade Safety, Full Control and More Peace of Mind

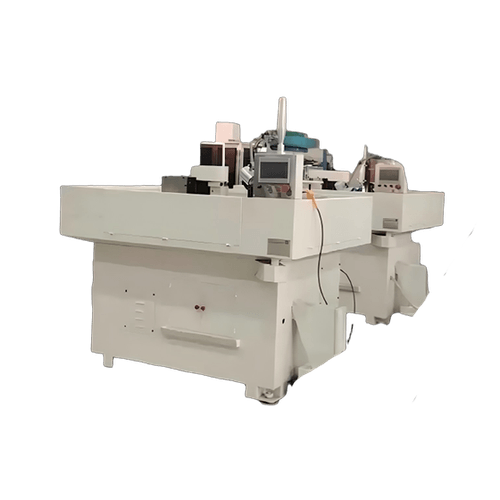

Small thread flange straight nut tapping machine

M6 small flange straight nut tapping machine

100% pass and stop

Verticality < 0.05mm

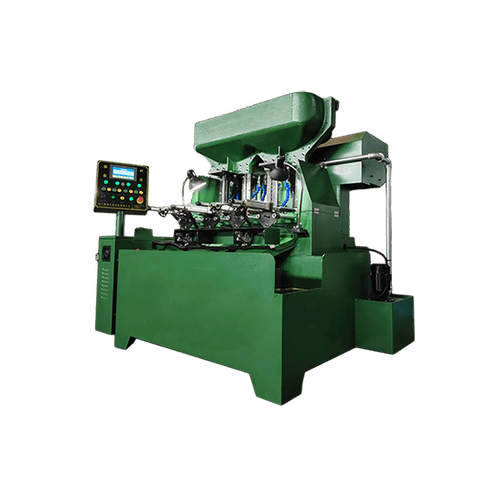

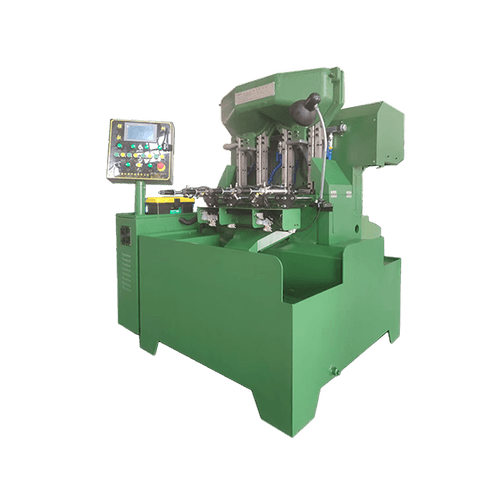

Fully automatic four-axis nut tapping machine

M20 fully enclosed four-axis hexagonal nut tapping machine100% pass and stop

Verticality <0.1mm.

PRODUCT

AllTapping machineDrilling machineCNC latheWasher assembly machineLocking machineSlotting machineNon-standard custom MachineAtherLoad More10000+

Buyer Praise

9800+

Successful Case

20+

Industry Expert

- https://www.google.com/maps/place/%E4%B8%AD%E5%9B%BD%E6%B5%99%E6%B1%9F%E7%9C%81%E5%AE%81%E6%B3%A2%E5%B8%82/@29.8699757,121.407152,11z/data=!3m1!4b1!4m6!3m5!1s0x344d6354630858f7:0x948723f846ccf173!8m2!3d29.868336!4d121.54399!16zL20vMDFsMzNs?hl=zh-CN&entry=ttu+8617706680382

Add: Ningbo City, Zhejiang Province, China

Tel: +8617706680382

Email: linda@hoporogroup.com